Quiet performance exhaust systems play a vital role in modern automotive engineering, balancing power, efficiency, and environmental factors while catering to drivers' preferences for quieter rides. These systems manage exhaust flow dynamics to reduce backpressure, optimize gas flow, and enhance handling dynamics through advanced materials and innovative designs. The benefits include improved fuel efficiency, boosted horsepower, refined vehicle control, reduced noise pollution, and increased driver comfort, making them especially appealing to urban dwellers and environmentally conscious individuals. Proper installation and material choice are crucial for optimal engine performance and durability.

In the pursuit of quieter, more efficient vehicles, quiet performance exhaust systems have emerged as a game-changer. This article delves into the intricate relationship between engine backpressure and these advanced exhaust designs. We explore how quiet performance exhausts mitigate backpressure, enhancing engine performance while reducing noise pollution. By understanding the impact on vehicle dynamics, we uncover the advantages and considerations for implementation, offering a comprehensive guide to this innovative technology.

- Understanding Engine Backpressure and Its Impact

- The Role of Quiet Performance Exhaust Systems

- Advantages and Considerations for Implementation

Understanding Engine Backpressure and Its Impact

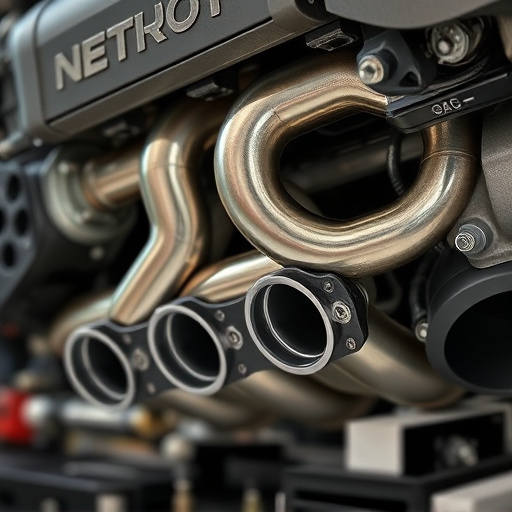

Engine backpressure refers to the resistance against the flow of exhaust gases leaving the combustion chamber. This is a crucial factor in determining engine performance and efficiency. When the exhaust system, including quiet performance exhaust systems, is designed with optimal backpressure in mind, it can significantly impact overall engine health and power output.

In vehicles equipped with quiet performance exhaust systems, such as cat-back exhausts, understanding backpressure becomes essential. These systems often incorporate advanced suspension components to manage noise levels while ensuring minimal impact on the engine’s backpressure. By carefully managing exhaust flow dynamics, these modifications can enhance engine breathing, allowing for better fuel combustion and improved overall vehicle performance, all without compromising the quiet operating conditions desired by many drivers.

The Role of Quiet Performance Exhaust Systems

Quiet performance exhaust systems play a pivotal role in modern automotive engineering. They are designed to balance power and efficiency while minimizing noise pollution, catering to both environmental regulations and driver preferences for quieter driving experiences. These systems achieve this by employing advanced materials and innovative designs that reduce backpressure within the engine, thereby enhancing overall performance.

The impact of quiet performance exhaust extends beyond noise reduction. By optimizing gas flow through carefully crafted intake components and tailored exhaust tips, these systems can improve fuel efficiency and boost horsepower. Additionally, they often incorporate suspension kits to further refine handling dynamics, creating a harmonious interplay between engine output and vehicle control. This holistic approach ensures that drivers not only enjoy quieter rides but also experience enhanced performance and maneuverability.

Advantages and Considerations for Implementation

Implementing quiet performance exhaust systems offers several advantages for vehicle owners and manufacturers alike. One of the primary benefits is the significant reduction in noise pollution, making it an eco-friendly option. This is particularly appealing to urban dwellers and those concerned with environmental impact. Moreover, quieter engines can lead to improved driver comfort, especially during long journeys or in heavy traffic, as it reduces the overall noise level inside the vehicle cabin.

When considering the adoption of quiet performance exhausts, several factors should be taken into account. For instance, while these systems are designed to minimize backpressure, proper installation is crucial to ensure optimal engine performance. Additionally, the choice of materials is essential; high-quality stainless steel or specialized alloys can enhance durability and corrosion resistance, ensuring the exhaust system keeps its efficiency over time. This is especially relevant when considering that a well-maintained exhaust system not only contributes to better fuel economy but also extends the life of other critical components, such as brake pads and intake components.

Quiet performance exhaust systems offer a compelling solution for reducing engine backpressure, enhancing overall efficiency, and providing a smoother driving experience. By seamlessly integrating advanced materials and innovative designs, these exhausts mitigate noise pollution without compromising power output. When considering implementation, it’s crucial to balance the environmental benefits against potential costs and maintenance requirements. Embracing quiet performance exhaust technology contributes to more sustainable and enjoyable motoring experiences in today’s evolving automotive landscape.